Jointly with Ampelmann, we developed the most energy efficient luffing system possible.

By using BHC technology, the Seaqualize luffing system smartly balances the telescopic gangway without the use of the traditional bulky, costly and energy consuming diesel power units.

Our system allows Ampelmann to take the next step in building energy efficient, fully electric Walk-2-Work gangways. The Seaqualize luffing system is fully offshore certified by DNVGL.

Why waste power, if you can simply balance it?

Benefits of the balanced luffing system:

Requires <1kW power for handling a 13m gangway

It’s the only solution for enabling fully electric heavy and long gangways

Greatly increases the time window for remaining safely landed during system emergencies

Seaqualize Balanced Luffing System

Milestones towards commercial tests

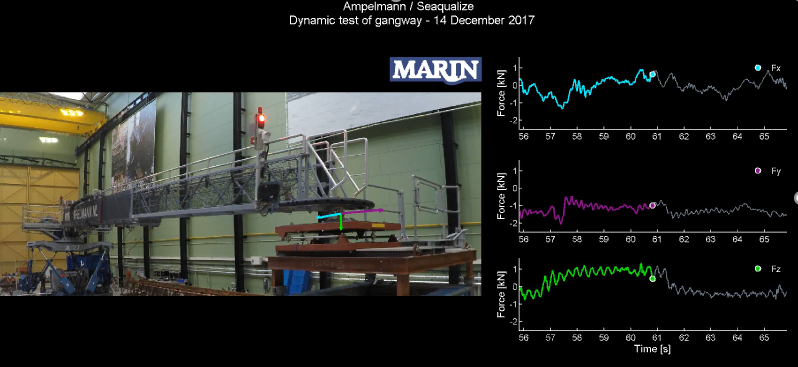

Together with our partners Ampelmann Operations, MARIN and TNO/ECN, we are building the first fullscale prototype of the balanced walk-2-work access gangway. We have tested all subsystems and final on-shore and offshore tests are planned for 2nd half of 2019

Concept development & simulations

We developed the mechanical, hydraulic and electrical concepts. We have all design and simulation capabilities and knowledge in house to validate concepts up to the stage where we exactly know which hardware components are required.

Subsystem testing

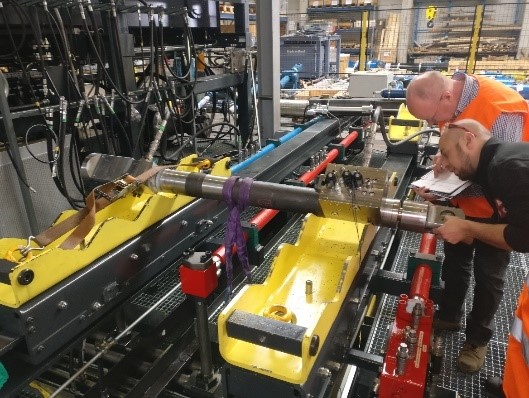

We pre-test separate new sub-systems to ensure they work. Together with independent maritime research institute MARIN and Ampelmann, we have tested for example the passive luffing system separately. We showed that a well-balanced gangway can be moved by hand without the support of any form of powered actuation. We have performed testing both at the Ampelmann assembly location, as well as our own research lab in Utrecht.

Engineering & integration

The first phases of basic design are done in-house. We ensured integration of our new system by, for example, redesigning the existing gangway.

Supplier coordination

We work together with our suppliers on final design and during the fabrication phase, to ensure required specifications & certification points are met, and ad-hoc improvement solutions are implemented.

Software development

We internally develop CU and PLC software for all control & electrical functions of the luffing axis, ensuring the software fits easily into the existing gangway software

Assembly, testing & commisioning

Ampelmann and Seaqualize assembled the full scale prototype and ran through full onshore tests in the Ampelmann OZB assembly hall. Offshore testing is planned for 2nd half of 2019.

The best way to show your gangway is fully balanced: lifting it by hand!

Below a video of a perfectly balanced Ampelmann gangway, using Seaqualize Balancing technology. The 1mT telescopic gangway is nicely balanced over its full reach, requiring very little (hand-)power to put into a different position: no need for heavy actuators

Certification

The design and fabrication of the Seaqualize luffing balance assembly has received DNVGL type approval, based on ST 358 and CG 0194.

This project is executed with support of the Topsector Energy of the Dutch ministry of Economic Affairs